RUBBER COMPRESSION SET

On 28-01-2013

ALL YOU HAVE TO KNOW ABOUT RUBBER COMPRESSION SET

Rubber can not be compressible. A seal housingwill therefore be calculated to allow the seal deformation while keeping its elastic property.

But chemical chains combination, fixed in a certain state by the vulcanisation operation in a mould, will tend to accommodate between them in order to fit inside the housing form under compression, temperature, environmentand chemical reactions.

Observaton of a used O-rng will show that it has lost its original aspect. It has more or less taken the shape of the groove.

This is called COMPRESSION SET.

If a rubber part can show this phenomenon while being used, rubber compound will be formulated so that this deformation is kept as low as possible.

COMPRESSION SET is a good indicator to characterise an efficient rubber "spring".

COMPRESSION SET measure

In a standard laboratory temperature, a rubber sample with a defined thickness is compressed at a certain rate.

This rate being maintained, the sample is held so at a defined temperature and during a specified time.

After stopping the compression force (immediately after taking it out of the oven), and after a defined time to allow the sample to come back to the room temperature, rubber thickness is measured again.

In the particular case of low temperature measurement, and after stopping the compression process, the rubber sample

is maintained at this low temperature and measured from time to time in order to evaluate the COMPRESSION SET.

RUBBER SAMPLES and EQUIPMENT

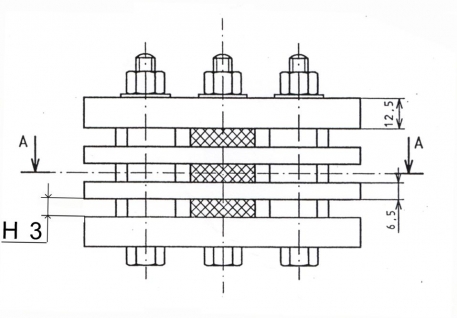

according to NF ISO 815-1 norm :

- A type rubber sample : cylindrical disc with 29,0 mm diameter and 12,5 mm thickness

- B type rubber sample : cylindrical disc with 13,0 mm diameter and 6,3 mm thickness

A type rubber sample is preferred because dimensions assure a higher measurement precision.

B type sample can be used when it can be issued from a rubber part.

Required equipment : 2 compression plates, spreading parts and clamping device.

EQUIPMENT TYPE :

Compression plates are made of chromed or stainless steel, and must be rigid and bigger than the compressed rubber sample.

Spreading parts are made of steel and allow for required compression. Their size, shape and position are adapted to avoid any contact with compressed rubber samples.

To get a 25% compression ratio, the plate thickness is 9,38 mm for A type rubber sample,, and 4,72 mm for B type sample.

A screw clamping device is convenient, but for low temperature tests, a fast unclamping device is required.

An oven or a cold room is used to maintain required temperatures.

TESTING CONDITIONS

Usual times are 24 hours, 72 h, 168 h, or 168 h multiple.

Normal temperature is 23° C ± 2°.

For high temperatures and according to elastomers types and applications : 40° C, 55° C, 70° C, 85° C, 100° C, 125°C, 150°C, 175° C, 200° C, 225° C, 250° C.

For low temperatures : 0° C, -10° C, -25° C, -40° C, -55° C, -70 C, -80° C -100° C.

RESULTS

knowing that : H1 is the initial sample thickness

H2 is the final thickness after testing

H3 is the device clamping thickness

H1 - H2

formula : --------- x 100 = deformation %.

H1 - H3

Test sample before proof

Test sample after proof

A low value means that tested rubber has a good capacity to keep its sealing properties.

Duration and tested temperature have an important influence on results. Temperature will be chosen to avoid toomuch rubber properties modification.

It is commonly admitted that for a 70 hours test :

• at 100° C for NBR

• at 200° C for silicones and Fluoro-carboned rubber

A less than 20% COMPRESSION SET is a good result andgives satisfactory compression results, and therefore a good functional sealing capacity.

In our laboratory, we regularly check our own rubber compounds COMPRESSION SET, as well as for our ready to use compounds to guarantee qualiy of our production for our customers.

- NEWS N°184, Production of bipolar plates for fuel cells using the LSR injection process, type 3025-40 or EPDM, FKM, ...

- NEWS N° 182 - The CHEVALIER - CLERET - ELTEC Group in summury

- CHEVALIER CLERET ELTEC SILICONES - CAOUTCHOUCS ECO RESPONSIBLE - French Business Climate Pledge 11/12/2017

- FLUORINATED ELASTOMER FKM FPM RUBBER FOR PHARMACEUTICAL USES & FOOD CONTACT APPLICATIONS ALSO STERILIZABLE

- ELASTOMERS COMPARATIVE – TPE TPV THERMOPLASTICS ELASTOMER - HCR HEAT CURING ELASTOMERS

- TRIPLE ANNIVERSARY FOR CHEVALIER CLERET ELTEC RUBBER AND SILICONE AND LSR

- SELF LUBRICATED NITRILE NBR COMPOUND

- NITRILE NBR FOR GAZ APPLICATIONS NF EN 549

- RUBBER PARTS INSPECTION & "IN PRODUCTION" FUNCTIONNEL TESTS

- HOW TO GET MOULDED RUBBER PARTS & THERMOPLASTIC TP + SELF BONDING LSR CO INJECTION

- EXTREME PERFORMANCES FOR RUBBERS AND NEW OPPORTUNITIES THROUGH FLS FFLS FLUORO LIQUID SILICONE NEW GRADES AVAILIBITY

- RUBBER AND SILICONE LSR THERMAL EXPANSION

- RUBBER REUSE ( HIGH TEMPERATURE VULCANIZATION / CURE ELASTOMERS; SILICONES & LIQUID SILICONE RUBBERS / LSR)

- http://en.wikipedia.org/wiki/Synthetic_rubber

- http://en.wikipedia.org/wiki/Silicone

- HYBRIDS : LIQUID SILICONE RUBBER LSR SELF BONDING ON TP - THERMOPLASTIC (2on2) also named "self bonding lsr silicone"

- HYBRIDS : RUBBER BONDING ON METAL (1on2) also named "rubber metal"

- RUBBER FRICTION

- SILICONE AND RUBBER TEARING

- SILICONE AND RUBBER PARTS STORAGE

- RUBBER AND SILICONE TENSILE STRENGTH AND ELONGATION AT BREAK

- RUBBER TANGENT DELTA (TAN DELTA)

- RUBBER'S RESILIENCE

- YOUNG MODULUS FOR RUBBER

- RUBBER PARTS ASSEMBLING & MOUNTING

- RUBBER HARDNESS MEASUREMENT

- RUBBER COMPRESSION SET

- TO BE SEEN IN PHARMAPACK 2012 - Paris

- SILICONE AND ELASTOMERS SELF LUBRICATION

- ELASTOMERS POST CURING

- CUSTOM LSR COLORS

- 7 th TECH DAYS

- 6èmes journées techniques