SILICONE AND RUBBER TEARING

On 05-02-2013

ALL YOU HAVE TO KNOW ABOUT RUBBER TEARING

Apart from elastomers basic mechanical characteristics (tensile strength, breaking resistance extension..), measuring tearing resistance is often very useful for rubber users as well as for rubber developpers.

In fact, a rubber part can be exposed to severe stresses during its use. In that case, even if resistance characteristics to pressure or to repeated efforts are sufficient, mounting conditions (electrical contact blades insertion) or environment (like stone or chips projections) can be very hard and therefore demanding for a high rubber tearing resistance.

Also, during its production, a rubber part can be submitted to high tearing risks, this being already obvious during the demoulding operation.

Rubber tearing resistance is measured on a rubber test sample (test specimen) (with a 2 mm thickness) with a dynometer. Traction speed is 500 mm per minute, and tearing value is measured in kg/cm or in Mg/m.

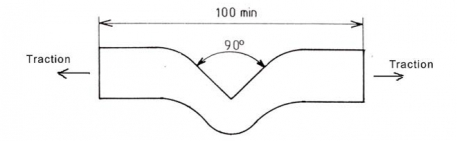

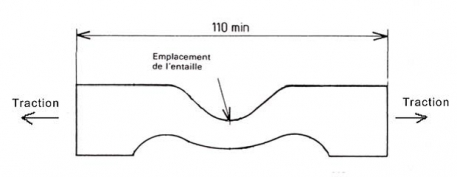

There are several types of rubber test samples (test specimen), from which 2 types are more commonly used; NFT 46-007 norm describes the test sample shape : angle shaped and curved shaped test samples.

The angle shaped test sample has the advantage, with its curved 90° angle, to have a fragile zone inside of the angle. This test sample is punched out in a rubber sheet.

The curved shaped test sample is also punched out, but a 1 mm notch is made with a cutting tool in the middle of the curve to create a fragile (critical) zone. This notch makes this test more severe than with an angle shaped test sample.

notch ↓

We use the angle shaped test sample type in our laboratory. We make these tests when we qualify our mixtures and materials, when we compare them with our customers technical specifications, and when we check our products quality.

Rubber tearing resistance is generally very good with natural rubber, polyurethane, and with some polychloroprene. These materials have no reinforcement charges and have outstanding mechanical properties. For other rubbers, additives can be used to ensure approaching or similar mechanical properties.

Some values to fix above mentionned :

“Natural rubber” or polychloroprène rubber : from 30kg to 55 kg /cm

Silicones : from 10kg to 30 kg /cm

- NEWS N°184, Production of bipolar plates for fuel cells using the LSR injection process, type 3025-40 or EPDM, FKM, ...

- NEWS N° 182 - The CHEVALIER - CLERET - ELTEC Group in summury

- CHEVALIER CLERET ELTEC SILICONES - CAOUTCHOUCS ECO RESPONSIBLE - French Business Climate Pledge 11/12/2017

- FLUORINATED ELASTOMER FKM FPM RUBBER FOR PHARMACEUTICAL USES & FOOD CONTACT APPLICATIONS ALSO STERILIZABLE

- ELASTOMERS COMPARATIVE – TPE TPV THERMOPLASTICS ELASTOMER - HCR HEAT CURING ELASTOMERS

- TRIPLE ANNIVERSARY FOR CHEVALIER CLERET ELTEC RUBBER AND SILICONE AND LSR

- SELF LUBRICATED NITRILE NBR COMPOUND

- NITRILE NBR FOR GAZ APPLICATIONS NF EN 549

- RUBBER PARTS INSPECTION & "IN PRODUCTION" FUNCTIONNEL TESTS

- HOW TO GET MOULDED RUBBER PARTS & THERMOPLASTIC TP + SELF BONDING LSR CO INJECTION

- EXTREME PERFORMANCES FOR RUBBERS AND NEW OPPORTUNITIES THROUGH FLS FFLS FLUORO LIQUID SILICONE NEW GRADES AVAILIBITY

- RUBBER AND SILICONE LSR THERMAL EXPANSION

- RUBBER REUSE ( HIGH TEMPERATURE VULCANIZATION / CURE ELASTOMERS; SILICONES & LIQUID SILICONE RUBBERS / LSR)

- http://en.wikipedia.org/wiki/Synthetic_rubber

- http://en.wikipedia.org/wiki/Silicone

- HYBRIDS : LIQUID SILICONE RUBBER LSR SELF BONDING ON TP - THERMOPLASTIC (2on2) also named "self bonding lsr silicone"

- HYBRIDS : RUBBER BONDING ON METAL (1on2) also named "rubber metal"

- RUBBER FRICTION

- SILICONE AND RUBBER TEARING

- SILICONE AND RUBBER PARTS STORAGE

- RUBBER AND SILICONE TENSILE STRENGTH AND ELONGATION AT BREAK

- RUBBER TANGENT DELTA (TAN DELTA)

- RUBBER'S RESILIENCE

- YOUNG MODULUS FOR RUBBER

- RUBBER PARTS ASSEMBLING & MOUNTING

- RUBBER HARDNESS MEASUREMENT

- RUBBER COMPRESSION SET

- TO BE SEEN IN PHARMAPACK 2012 - Paris

- SILICONE AND ELASTOMERS SELF LUBRICATION

- ELASTOMERS POST CURING

- CUSTOM LSR COLORS

- 7 th TECH DAYS

- 6èmes journées techniques